Dynamic balancing services in Surat is the process of refinement and servicing that aids in the efficiency and sustenance of industrial apparatuses. Some machinery in Surat, a city thronged with industries like textiles, chemicals and diamond cutting, may suffer from significant downtimes which could mean heavy losses. This is why dynamic balancing services in Surat are so important. By maintaining the correct angle of balance, equipment productivity can be increased significantly while repairs and downtimes can be reduced.In this article, we thoroughly examine the processes and benefits as well as the vital factors to look for while selecting dynamic balancing services in Surat to ensure that the right decisions are made.

What is Dynamic Balancing Services in Surat?

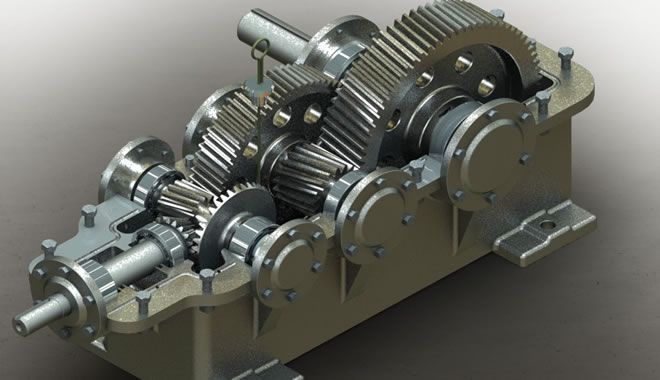

Dynamic balancing refers to the correction and measuring of an imbalance in rotating machines to allow for smoother functioning while reducing wear. Some common results of imbalance include:

Space Out: places with a lot of vibrations

Bearing Quiet Death: premature failure of bearing supports

Wear Me Loudly: Amplified sound.

Operational underperformance.

Dynamic balancing services in Surat provide precision balancing solutions for industries that depend on high speed machinery.

What Makes Dynamic balancing services in Surat Useful for Companies in Surat?

The business environment pertaining to Surat’s industry is balanced and accurate. Machines like motors, pumps, fans, and turbines are fundamental to operations in these sectors. Here’s why dynamic balancing services matter:

Increased Lifespan of Equipment: Balanced equipment is subject to less stress, and as a consequence, is able to operate for longer.

Reduced Downtime: Imbalanced machinery often results in breakdowns that are costly and time-consuming. Balancing machinery lowers these chances.

Cost Effective: Balanced machines waste less power, translating to lower electricity bills.

Safety: Operators are provided with a safer workplace because of the reduction in vibrations.

In What Order Do the Steps of Dynamic Balancing Proceed?

Step 1: Imbalance Inspection

Imbalance diagnostics are done using sophisticated equipment such as vibration analyzers and laser sensors on rotating parts of machinery.

Step 2: Balance Adjustment

If there are any diagnostic results that weigh let’s say too much or too little, material gets added or removed from the area in question. Balance Adjustment can take place:

On-site: Where apparatus is cumbersome to transport due to its size.

Off-site: In specialized workshops that have specific balancing tools.

Step 3: Compliance Test

After the balancing of machinery takes place, the equipment is checked to make sure it works fine and meets the industry regulations.

The Different Dynamic Balancing Services Offered

Dynamic balancing services for various industries and machine types are available in Surat. These are the primary types of services offered:-

1. Field Balancing

Balance your equipment right at your place, saving you transport costs and times.

2. In-Shop Balancing

Specialized machines are available for balancing smaller parts like rotors and impellers.

3. Predictive Maintenance

Utilizing dynamic balancing with predictive maintenance aids in addressing problems that can escalate towards foreseen issues.

Choosing The Dynamic balancing services in Surat

In choosing a service provider, these factors should be given consideration:-

Experience and Expertise

Preferred companies should have a history of working with different sectors and mastered complicated machinery parts.

State-of-the-Art Equipment

Balanced diagnostic and balancing tools guarantee accurate service, so ensure the service provider uses these.

On-Site and Off-Site Capabilities

The flexibility of service provision is very important especially when large industrial machines are on site.

Customer Reviews And Testimonials

Service standards can be evaluated by checking feedback from past clients.

Compliance With Industry Standards

Dynamic balancing providers must comply with ISO standards.

Benefits of hiring professionals for dynamic balancing

Dynamic balancing in Surat is best done by experts for the following reasons:

Cost Benefits: Avoid mishaps of break downs and breakages that need heavy spending.

Time Benefits: Minimal distract to essential work results from quick response time.

Precision Results: Utilizing advanced equipment guarantees accuracy in balance performance testing.

Custom Solutions: Services designed with your specific machinery requirements in mind.

Who Uses Dynamic Balancing Services in Surat

Dynamic balancing services can be utilized in numerous fields including:

Textiles: High Speed looms and motors used in the textile sector of Surat needs to be balanced frequently.

Chemical Processing: Pumps and fans in chemical processing plants need to work properly for safety reasons.

Diamonds and Jewelry: Diamond cutting machines are precision tools that require perfect functioning.

Construction: While vibrating compressors and generators are operated, there is little to no vibration.

Ways To Achieve And Maintain Balanced Machinery

Regular Inspections: Be sure to schedule regular vibration analysis as a part of the maintenance program to discover any indication of imbalance.

Lubrication: Put bluntly, all moving parts must be lubricated to avoid friction.

Alignment Checks: Shaft misalignment is a big contributor to an unbalanced machine, so regular checks for alignment are vital.

Proper Installation: New machines should never be installed without following the instructions of the manufacturer.

Common Signs Your Machinery Needs Balancing

You should be looking for Dynamic balancing services in Surat if you notice some of the common signs such as:

Excessive vibration

Abnormal noise

Bearing or seal breakage regularly

Certain components wearing more than others

Loss of efficiency

Star Balancing: Your Trusted Partner for Dynamic balancing services in Surat

Here at Star Balancing, we are proud to deliver remarkable balancing services to different industries in Surat. Here’s what makes us different from the rest:

Experienced Team: Our technicians have years of experience in different types of machinery.

Cutting-Edge Tools: We work with the most modern diagnostic and balancing tools.

Customer-Centric Approach: Solutions designed for you and your requirements.

Comprehensive Services: We offer everything from field balancing to predictive maintenance.

Contact us today to experience our remarkable Dynamic balancing services in Surat.

(FAQs)Dynamic balancing services in Surat?

Q1: How much do balancing services cost in Surat?

We can not give a fixed cost as it is based on the type and size of the machinery. Please get in touch with us for a quote.

Q2: How often should you perform balancing services?

This is not a straightforward question and varies depending on how the equipment is used and the conditions under which it is operated. We recommend regular inspections every 6-12 months.

Q3: Is it possible to perform dynamic balancing while on-site?

Yes, on-site balancing is possible on large equipment in order to keep down time low.

Q4: What Instruments Are Used During Dynamic Balancing?

Balance contractors use vibration analyzers, laser alignment systems, and balance machines, among other tools.

Q5: What Problems Can Be Solved By Dynamic Balancing In Industrial Machinery?

Balancing reduces vibrations, improves safety, prolongs the equipment’s life, increases productivity, and improves efficiency.

Conclusion

In conclusion, dynamic balancing is an important service in assuring the performance and safety of industrial machinery in Surat. Working with Star Balancing eliminates vibrations and boosts productivity.Contact us today to have your equipment inspected and eliminate all disruptions and vibrations with the best dynamic balancing services in Surat.